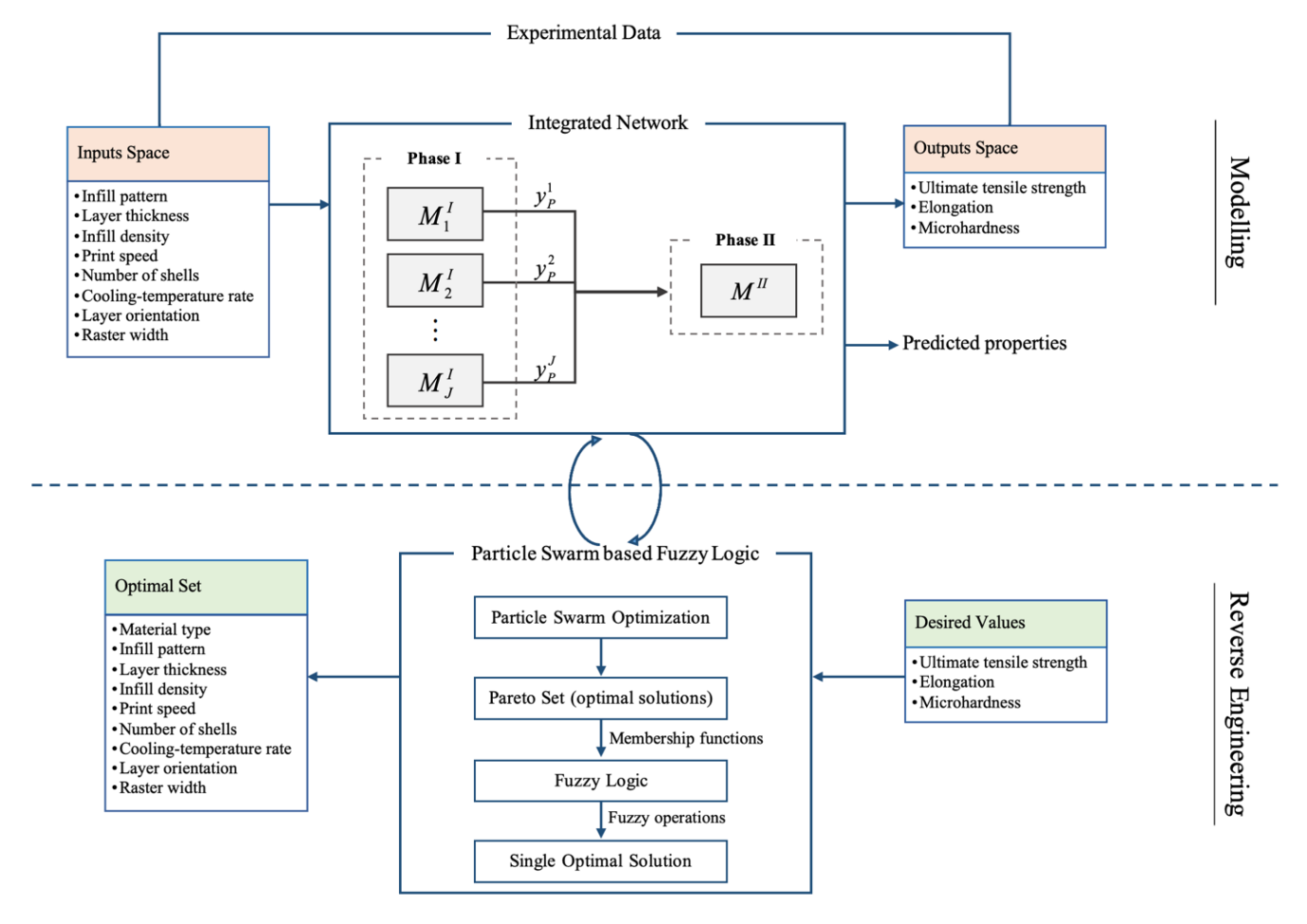

This project aims to develop both the 3D printing industry in Jordan which is still at its infancy and the healthcare manufacturing industry, by producing 3D printed medical implants right from the first time for the first time in Jordan. Medical implants were systematically designed and then 3D printed right from first time by exploiting the power of Machine Learning (ML) and Artificial Intelligence (AI) for carefully guiding the manufacturing 3D printing process towards optimal and pragmatic designs, as shown in Figure 1. For this purpose, a radial based integrated network was proposed to map the most significant 3D printing parameters to the mechanical properties of the 3D printed implants. Such an integrated network was then exploited in a reverse-engineering framework based on a novel integration of particle swarm optimization and fuzzy logic to identify the optimal 3D printing parameters that need to be employed to produce 3D printed implants with predefined mechanical properties, as shown in Figure 2.

Figure 1. The Right-First-Time framework.

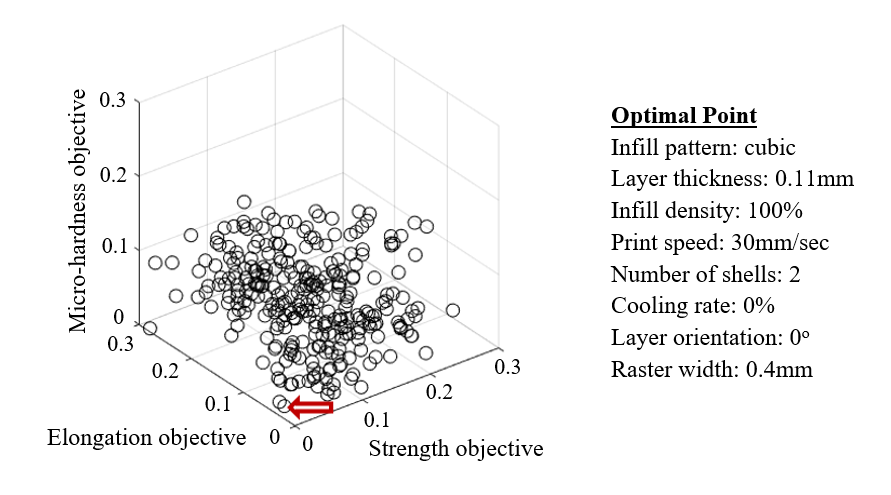

Figure 2. The optimal 3D printing parameters that need to be used to produce 3D printed implants with an ultimate tensile strength value of 100MPa, an elongation value of 22% and a micro-hardness value of 30.

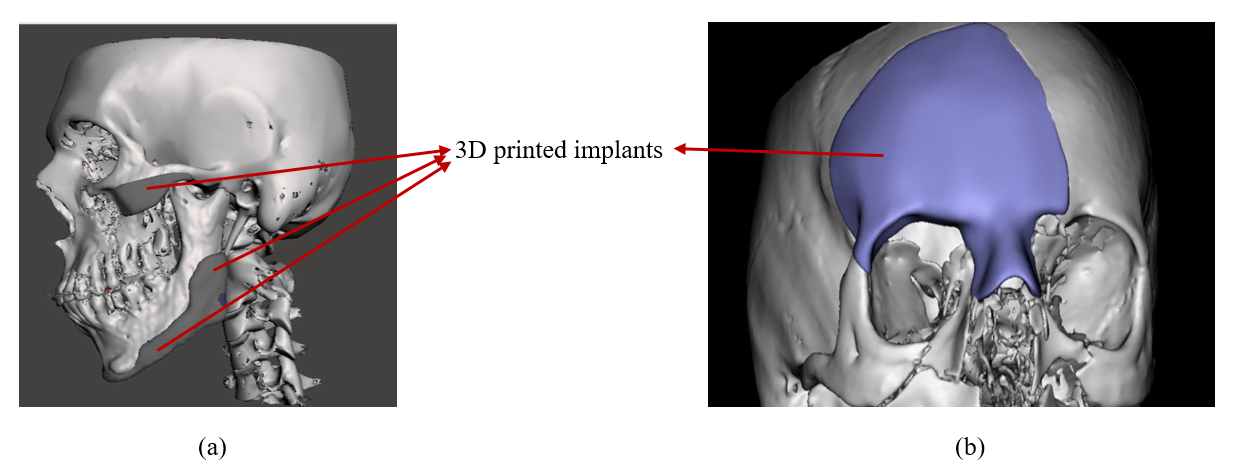

For the first time in Jordan, three medical implants were produced for a 21-year-old patient suffered from Hemifacial Microsomia. Furthermore, various skull implants were also produced for two patients suffered from skull lacerations, as shown in Figure 3. To 3D print these implants, CBCT x-ray scans were taken for the patients and represented in the Digital Imaging and Communications in Medicine (DICOM) format. Various 3D design programs, namely, Meshmixer®, Slicer® and Blender® were then employed to design patient-specific implants by mirroring and simulating the non-affected sides. Based on the required mechanical properties specified by surgeons, such implants were printed by the FUNMAT HT 3D printer using Polyether Ether Ketone, as a biocompatible material, using the optimal 3D printed parameters defined by the reverse-engineering structure. All implantation operations carried in Jordan under strict medical and ethical supervision proved very successful, and as a result, other similar patient-specific implants will be produced in Jordan in the near future.

The cost of these implants was less than 10% of the cost of the implants produced by other leading manufacturers based in Europe, leading therefore, to treatment costs being reduced significantly, and with better mechanical properties compared to off-the-shelf implants.

Figure 3. The 3D printed patient-specific implants produced.

Project Team:

This project was a collaboration between two academic institutions, namely, The University of Jordan (UOJ) and The University of Sheffield (UOS), and Printie 3D, as an industrial partner. The main aim of this project was ascertained and will be expanded by extraordinary enthusiasm and expertise of the project researchers:

- Dr. Wafa' H. AlAlaween (Lead, UOJ)

- Professor M Mahfouf (UOS)

- Dr Belal M.Y. Gharaibeh (UOJ)

- Mr. Ahmad Al-Soussi (Printie 3D)

- Professor Ashraf E. AbuKaraky (UOJ)

Funding:

This project was financially supported by The Royal Academy of Engineering (UK) and Industrial Scientific Research and Development Fund-The Higher Council for Science and Technology (Jordan).

Publications:

- W.H. AlAlaween, A.H. AlAlawin, S.O. AbuHamour, B.M.Y. Gharaibeh, M. Mahfouf, A. Alsoussi and A.E. AbuKaraky, Fuzzy particle swarm for the right-first-time of fused deposition, Journal of Intelligent & Fuzzy Systems, 2023.

- W.H. AlAlaween, O.A. Abueed, B.M.Y. Gharaibeh, A.H. AlAlawin, M. Mahfouf, A. Alsoussi and N.T. Albashabsheh, The development of a radial based integrated network for the modelling of 3D fused deposition, Rapid Prototyping Journal, 2023.

- W.H. AlAlaween, A. Alalawin, B.M.Y. Gharaibeh, M. Mahfouf and A. Alsoussi, An Interval Type-2 Fuzzy Logic System for the Simulation of Fused Deposition, International Conference on Electrical, Computer, Communications and Mechatronics Engineering (ICECCME), Maldives, 2022.

- B.M.Y. Gharaibeh, A.A. Salaimeh, M.W. Jararweh, A. Al-Omari, W.H. AlAlaween and M. Mahfouf, Correlation of Optical Properties to Mechanical Degradation of 3D Printed Thermoplastic Polyurethane Polymers Subjected to Gamma Irradiation, International Conference on Electrical, Computer, Communications and Mechatronics Engineering (ICECCME), Maldives, 2022.

- W.H. AlAlaween, A. Alalawin, B.M.Y. Gharaibeh, M. Mahfouf and A. Alsoussi, A Type-1 Fuzzy Logic System for the Modelling of Fused Deposition, International Conference on Research in Science, Engineering and Technology (ICRSET), Barcelona, Spain, 2022.